Vision Recognition in Production

What is Vision Recognition?

Vision recognition technology uses cameras and software to acquire and process images for tasks like counting objects, detecting colors, measuring size, or determining orientation. Within vision recognition are subcategories such as machine vision and computer vision, which effectively do the same thing; look and evaluate. We created our own vision system by writing our own software and using a regular camera —but this video from Cognex shows some good examples of what can be done with a vision system.

Design Ready Controls and Vision System

Technology like this has been around since the 1930s, but only recently have we seen opportunities to use it in our quality systems, to help with high-resolution photographs we take before shipping a panel. These pictures help us communicate with customers after a panel has shipped.

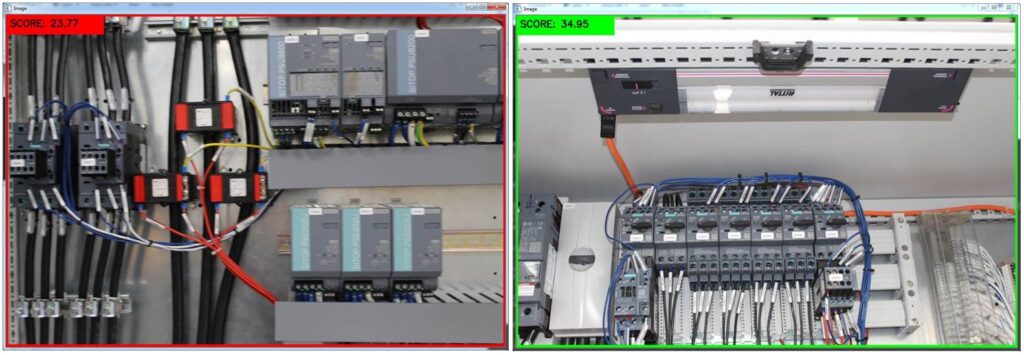

To implement this new process, our test and automation team and the individuals in Quality Control Finals (QCF) embedded an algorithm in our Automated Manufacturing Expert (AME®) paperless system that evaluates picture focus and overall quality. If the picture is out of focus, the operator is instructed to review the photo and take another picture if necessary. (See below)

Another system we hope to use, which is still in the proof-of-concept phase, is a vision system that inspects a control panel, verifies that device ID labels are all present, and confirms that the correct wire colors terminate at the right locations. Other applications will probably follow these two.

Vision recognition technology is used in welding systems, security systems, face recognition, self-driving cars, and more. If these two projects help us improve product quality and process flow, as we expect, other applications are sure to follow. For example, we hope it can help us verify component identity and placement on our control panels.

Benefits of Vision Recognition

Vision recognition can assess quality quickly and accurately without human interaction, reducing or eliminating the risk of human error. This makes the technology a valuable asset in any manufacturing process. If you want to test and use it yourself, online resources are easy to find. You can get set up and started without much equipment.

A vision system can be based on a simple laptop and webcam; more advanced implementations feature purpose-built cameras, dedicated processors and specifically calibrated lighting systems. If your idea works with a minimal system, it will work with a larger scale system. My advice is to start small and work out your proof of concept before investing in specialized equipment.

A thoughtfully designed machine vision system is faster, more accurate, and more consistent than human inspection methods. No matter what your application, I can promise one thing about using machine vision: You will see things in a new and better way.