Buffer Monitor Tool at Design Ready Controls

Process Status and Product Flow

Tasks, Buffer and Flow

In production line manufacturing, each step takes time. Some take longer because of things like labor-intensive detail work or inspection requirements. Anticipating task times and buffers accurately helps us plan for efficient, effective production. The term “buffer” or “buffer zone” is essentially the work you have in between work centers.

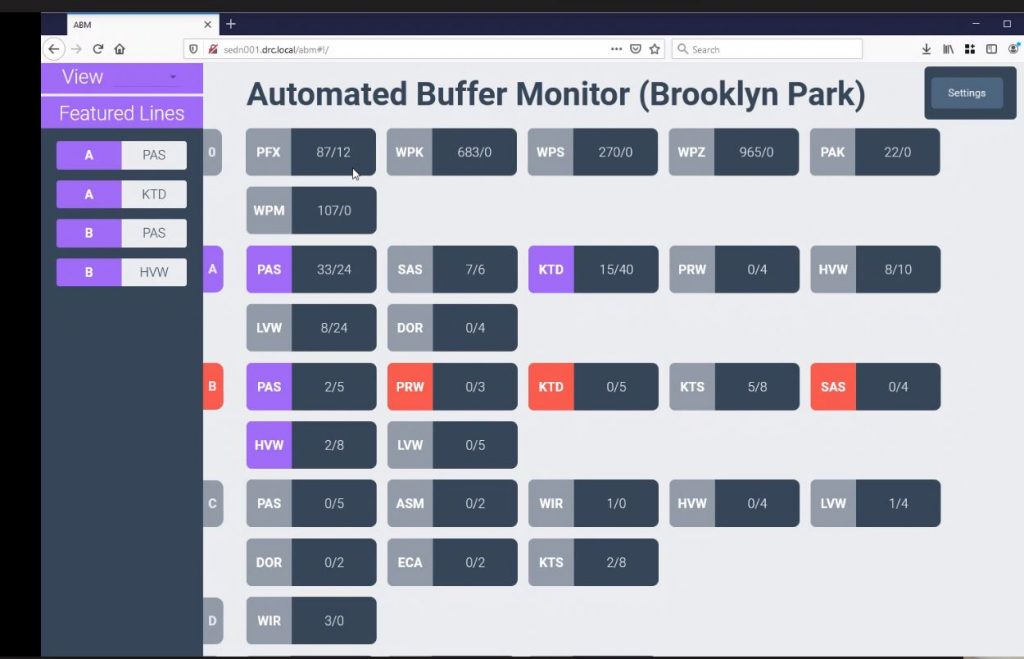

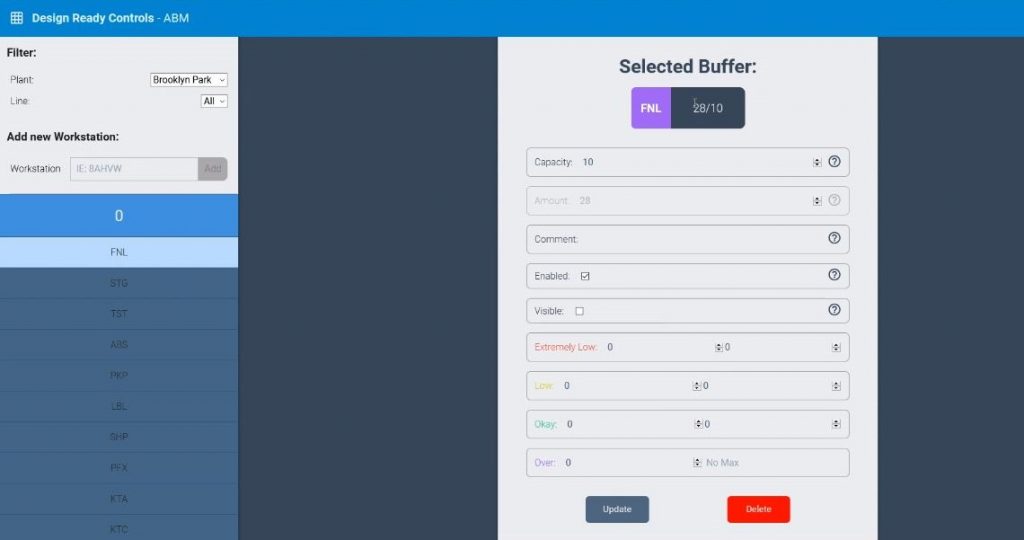

Production supervisors need to know where control panels are at any given moment. On our production floor we always want to have an amount of work in between each work center (the buffer or buffer zone), so no work center needs to wait for previous work centers to be done, for them to have work. However, we also do not want too much work sitting in a spot either. To track this our software team created an application called the Buffer Monitor. The buffer monitor helps production supervisors or anyone else quickly look at the entire plant level – with quick color identification. It will let them know if one of the buffers are no longer within the boundaries for the minimum and maximum, we have set.

How It Started

One of our engineers and a production supervisor had requested the ability to track panel status and buffers for each production line. A member of our software team created a prototype using PHP, a server-side scripting language, to see if it was what they were looking for. Everyone liked it. From there we started filling it out with logic and gathering data from M1, our ERP system. It has been reworked with new feature requests such as notifications when a buffer hits a critical threshold, and views of panels that have incomplete Engineering In-Process Change (IPC) requests.

How It Evolved

This proprietary tool has been in development since 2016. The first version pulled data from M1 when an employee clocked in or signed into a job. Because people were inconsistent in the way they used the clock-in system, beginning stages of development had unreliable data. And because the tool was new, not many people had made a habit of using it yet. The next iteration relied on manual data input, which we quickly found was tedious and too much work.

How We Use It

The Buffer Monitor provides visibility to all production lines and their buffer zones. A supervisor on the production floor can categorize the data within the program to see specific lines and identify where flow is reduced. In lets them focus on a specific area and make fact-based decisions to shift employees and product to help ensure a smooth production flow.

What’s Next

We are still developing out requests from the latest iteration, and once these are completed these features will be “self-sufficient” meaning, the notifications will be sent out via Microsoft Teams or email automatically. The future state of monitoring and displaying is projecting this onto TV monitors around the production floor. This would be a benefit to knowing how production is doing by giving a live snapshot of were the product is.

Who Else Can Use It?

To implement a buffer monitor, you need to identify what you want it to do and have an idea of how it should look. For us, it originated in the engineering department. Through collaboration, engineering and our senior software developer were able to format the data in a usable way. The software engineering team could then put it all together in a presentable system.

Some ERP systems already have metrics and functions that can provide most of these functions. If that’s the case, your software development team may not need to be as deeply involved. You might just need someone who is familiar with your ERP system.

The Design Ready Controls Buffer Monitor provides a great visualization of product flow and any potential gaps. A system like this can benefit anyone who has a production line and product flow with work stations that depend on each other.