Nesting

Laser nesting is the process where we place flattened parts on a flattened sheet of material and take into consideration the machine time, material efficiency, downstream processes and product due dates. Design Ready Fabrication has broken CNC laser nesting into three different categories 1. Manual 2. Static, and 3. Automatic; using Amada’s VPSS Blanking Software. There is a purpose for each nesting category – to support different strategies, and provide unique benefits while the team works to determine the more efficient and effective way to fabricate metal

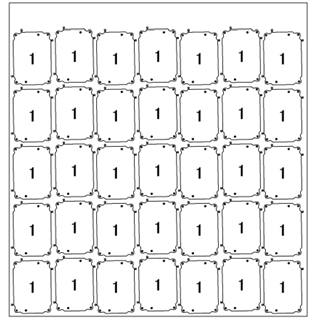

Manual Nesting

Manual nesting is exactly what it sounds like – manual. It is controlled directly by the team through a simple drag and drop of the parts on the sheet and taking into considerations the rotation, grain direction and part sequences are necessary. The accuracy and results of manual nesting are very dependent on the team member’s skills and knowledge of the nesting process.

Advantages:

- Maximizes control with cutting order and placement of parts

- Beneficial for special cases and problem parts

- Preferred when surface finish or edge quality is critical

Limitations:

- Success of nest dependent on programmers’ skill

- Time-consuming compared to automatic nesting

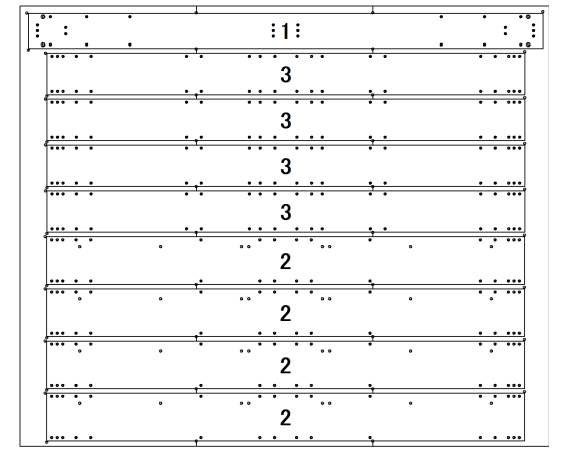

Static Nesting

Static nesting is a predefined layout of parts on a specific sheet used for repeat production runs. Unlike manual nesting, the arrangement does not change based on order mix or if quantity ordered fluctuates. Once the nest is created, it becomes a standard, repeatable template tied to a specific part group. We typically use this approach for long running parts with consistent quantities or assemblies such as enclosures.

Advantages:

- Extremely consistent results

- Fast setup and repeatability

- Simplifies scheduling and material planning

- Ideal for assembled products or dedicated production

Limitations:

- Not flexible for part mix variations

- Can lead to scrap if quantities don’t align with the fixed layout

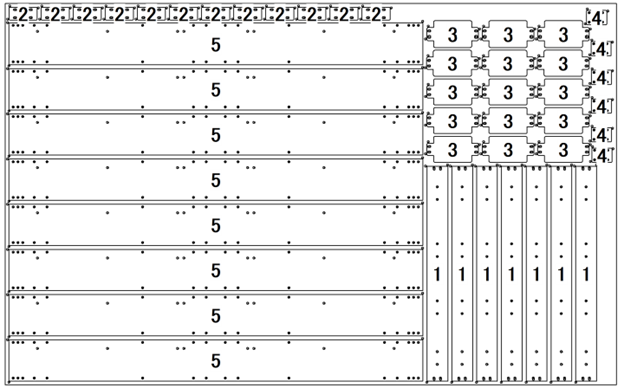

Automatic Nesting

Automatic Nesting functions with very limited user interaction. Select the parts you would like nested and let the system select the rest: material type, size, and thickness. Although the front end is simple, the program algorithm is complex. Throughout the process and when we add parts to it, the algorithm will add joints (if needed), provide the cut order as well as common cutting conditions. There are a lot of benefits to this strategy and best used for a high mix of parts and were forecasting from customers is not known.

Advantages:

- Minimal input from programmer

- Consistent results

- Optimized material yield in high-mix or high-volume environments

- Improved inventory management -less sheet sizes

Limitations:

- Utilize only for complex parts

- Tribal knowledge may be lost

- Nests generated maybe optimal on the screen but not for cutting

At Design Ready Fabrication, we use three different methods for nesting each with a strategic application based on the customer and product designs. Since the implementation of Amada’s VPSS Blanking Software in the middle of 2025, we have seen significant improvements in nesting efficiency and accuracy. These improvements are things such as bar coding of nesting files, clear part representation on nesting reports, and automatic material selection at the laser.